Innovation nmblFoam®

Direct injection for runners

Our worldwide unique nmblFoam® makes the difference.

Direct Injection:

Injection instead of gluing

- We save water and energy because the sole no longer has to be heated or melted

- We do not use adhesives, which can negatively affect the cushioning in the shoe by providing an additional intermediate layer or stiffening bonded materials

- We improve the connection between the sole and the upper because the midsole bonds firmly to the upper during production

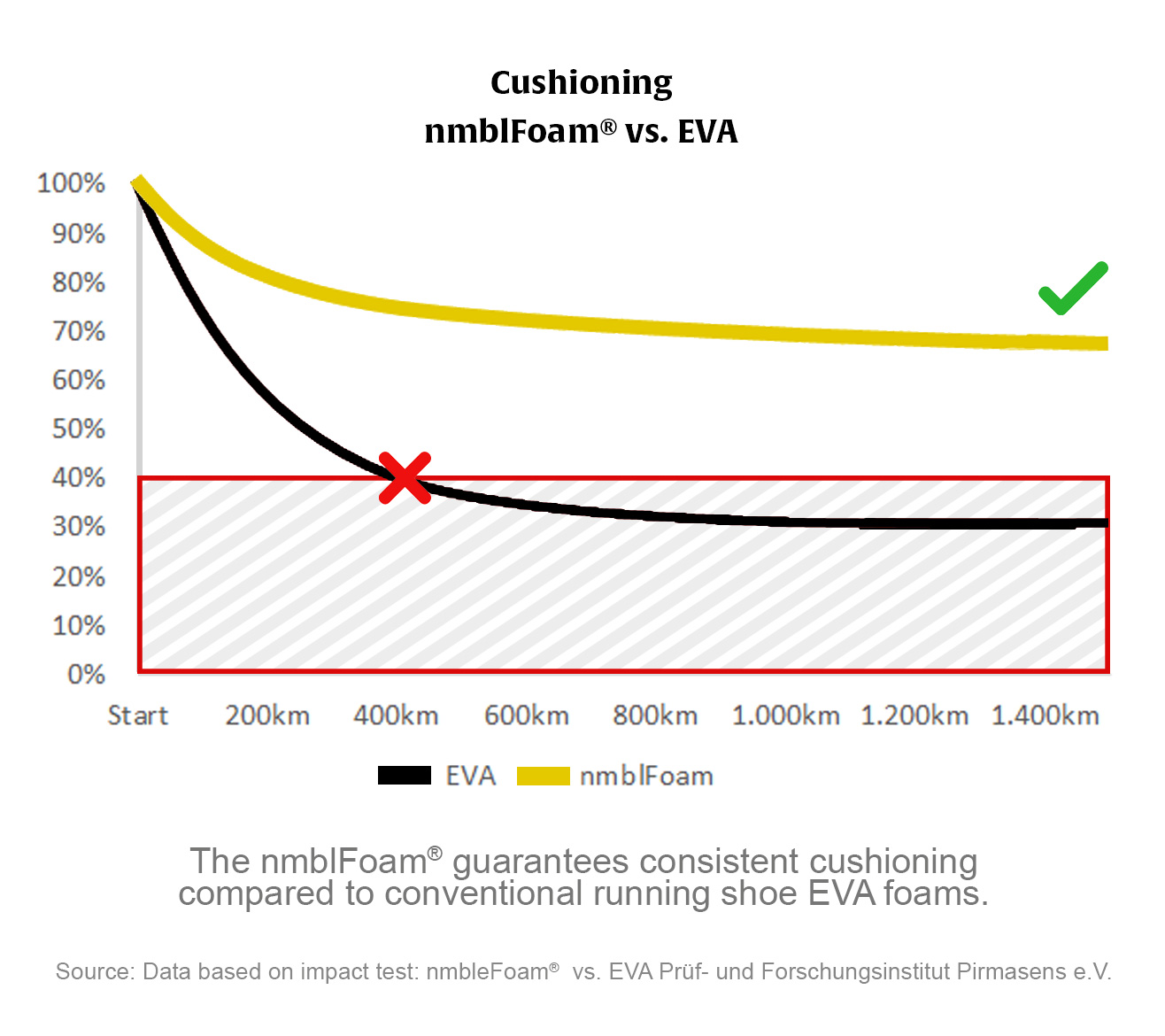

The advantages of PU

- the continuous dense foam is characterized by a deep and above all permanently consistent energy return

- ten times higher compression set (ability to return to its original shape) than conventional EVA foams

- longer durability

- hydrolysis free (advantage in hotter or more humid climates)

Automation reduces carbon footprint

Highly automated manufacturing also allows Joe Nimble to profitably move production of the Ultreya® back to Europe. This makes us less dependent on supply chains. And it brings us closer to the goal we aim for with every new development step: to produce our shoes in a CO2-neutral way for the foreseeable future.